July 2021 Covid blog

This blog aims to collect daily information about how the new Coronavirus COVID-19 is influencing garment workers' rights in supply chains around the world. It will be updated as new information comes in from media and the Clean Clothes Campaign global network. Information is posted as it comes in from the network and cannot always be double-checked.

26 March 2020

Global: The International Apparel Federation calls for solidarity in supply chains. In a statement the IAF says: "No buyer can be expected to sacrifice its own existence or the jobs of its employees to save its suppliers. But collaboratively searching for ways to reduce the damage to suppliers is not only an urgent need, but feasible. Solidarity in the face of this crisis means collaborating with industry members to bridge the income gap for workers and the demand gap for business. Operating with the objective of moving as much of the pain upstream in the supply chain will create breaches of trust that will be difficult to repair when we emerge from this crisis, IAF stated. “Choices made now will be scrutinized later”, IAF secretary general Matthijs Crietee said."

India: The Indian Ministry of Textiles appeals to buying houses and buyers not cancel orders and adds that delivering schedules can be reworked, payment plans can be extended.

Pakistan: The Sindh Tripartite Committee for Implementation of Labour Laws has asked employers in the province to implement the government orders of payment of salaries to all their staff during the lock down period and is monitoring the payment of wages and the ban on dismissal of workers during this period.

Sri Lanka: Dabindu collective reports that workers of the Katunayake Free trade Zone have been on lock down, unable to return to their home towns. There are around 82 companies in the Katunayake Free trade Zone and they provide service to signature brands such as Gap, H&M, Marks and Spencer, Tommy Hilfiger, Decathlon and Victoria's Secret. The majority of these workers are women and they reside in the boarding houses with their children. It has been estimated that there are about 20,000 workers are on lock down in these boarding houses. As the rooms in these boarding houses could accommodate 10-100 people, they live as groups. These workers use the same limited number of common lavatories and the public well. As the services of the garment factories were considered to be an essential service, the workers were forced work up until the moment the lock down was announced irrespective of their protest. The due date to pay their debts (used to pay for food) has expired and shops suffer from scarcity of essential grocery items. The police estimates that there are about 10,000 Man Power Agency workers. These workers have not received their daily payments and in have lost their jobs. Dabindu collective urges the Board of Investment, the Labour Department and the companies to provide these workers with requirements of food and medicine, make sure they receive their salary advances, provide them with health care, ensure that the shops have the essentials.

The latest news coming in from the CCC network is that workers who are on lock down in Katunayake are asked to gather in-front of the BOI premises tomorrow (27 March 2020) at 6.00 AM to go back to their places of origin. They will be transported with the help of the Military.

25 March 2020

Global: News keeps on coming in from around the world that brands are cancelling orders putting the livelihood of millions of workers at risk and factory owners associations calling upon brands to take responsibility and uphold orders or help solve the crisis.

Bangladesh: The IndustriALL Bangladesh Council, in which a large group of unions cooperate, has issued a press release after conducting an emergency meeting: "At present, due to Coronavirus the whole world including Bangladesh is in fear. In current situation Bangladesh is also at risk. Considering the overall situation in today’s emergency meeting IBC agreed on that,

- Until the situation gets in control all the factories including garments should announce leave with pay.

- In this hazardous situation no worker can be retrenched or terminated.

- If any worker gets sick or get infected all required measure relating to his/her proper treatment and safety must be ensured.

- Rationing system must be introduced for the workers.

- No factory should close or go into layoff without paying workers wages and dues.

- In emergency situation the government must provide cash support to the workers.

- Under the leadership of Labour Ministry tripartite monitoring taskforce including Government, BGMEA and IBC must be established.

- In this situation we are requesting buyers not to cancel any order."

Trade union federation BIGUF has sent a letter to the employers' organization BGMEA in response to the closure of the factories without mentioning proper provisions of for workers, calling for paid leave, medical assistance and ensuring food security for the workers.

Prime Minister Sheikh Hasina has announced a bailout package for export-oriented industries to fight the impact of coronavirus on the country's economy.

Cambodia: The Garment Manufacturers Association in Cambodia (GMAC) has called for collaboration from all stakeholders in facing the critical situation caused by Covid-19 pandemic calling upon brands not to cancel orders.

Cambodia is tracing migrant workers that returned to Thailand before the borders closed. Dy The Hoya, a programme officer at labour rights group Central, called on the government to ensure other migrant workers who could not return home are being taken care of in Thailand during this difficult time: “I hope the government will cooperate with Thai authorities to disseminate preventative measures against the COVID-19 disease to the workers and arrange to help them to continue staying in Thailand although their visas have expired,” he said. “The arrangement should also cover illegal migrant workers.”

Sri Lanka: CCC network organization FTZ-GSEU reports that almost all factories and offices have been closed except essential services. Most of the factories in the Free Trade Zones were opened until the declaration of a curfew despite earlier government requests to close. Some factory workers even went on strike demanding closure of their factories for health reasons. Because factories stayed open until the declaration of the curfew most of the workers could not travel to their villages. As a result they are stranded at their boarding houses near the Free Trade Zones. As they are still waiting for their monthly salary they do not have enough money to meet their needs. FTZ-GSEU wrote a letter to the Minister of Labour requesting him to intervene immediately by taking the following measures.

1. To advise to the Board of Investment of Sri Lanka (BOI) to supply food rations to boarding houses as they are the in charge of administrations of

Free Trade Zones.

2. To advice the companies to remit the salaries of these employees to their bank accounts immediately.

3. To advice through BOI to employers / Man Power Agencies to give Advanced payment to their employees.

FTZ-GSEU and the Women Center have launched a limited programme to provide food rations to the Free Trade zones employees. These boarding houses have up to 50 workers in each house without appropriate facilities. FTZ-GSEU raised this with the top level of the government and put up a video on social media requesting employees to contact the union if they need any assistance.

30 July

Bangladesh: Media reports that a fine of Tk 200,000 ($2,360.44) has been imposed on the Sparrow Apparels garment factory in the Laxmipura area of Gazipur for ignoring strict lockdown and government directives.

The fine was imposed after a mobile court raided the facility on Thursday. Executive Magistrate of the district administration Iqbal Hossain confirmed the matter.

Vogue magazine looks at the risks posed to the Bangladesh Accord being abandoned after less than a decade, and the way brands have chosen profits over garment workers during the pandemic.

Media reports that the American Apparel and Footwear Association has urged US President Joe Biden to increase the distribution of Covid vaccines to Bangladesh and other partner countries around the world to curb the recent increase in Covid deaths and cases.

Meanwhile, Bangladesh Garment Manufacturers and Exporters Association on Tuesday sought assistance from the US ambassador Earl Miller and head of the delegation of the European Union in Dhaka Rensje Teerink for rapid vaccination of RMG workers.

Media reports that State Minister for Labour Munnojan Sufian on Thursday urged all factory owners including readymade garment (RMG) not to announce any of their units lay-off and terminate any workers amid the ongoing strict lockdown.

The government has imposed a strict lockdown with industrial units closed under the restrictions.

The AAFA president Steve Lamar on Tuesday in a letter to Biden highlighted the difficulties COVID-19 has caused in several partner countries, including Vietnam, Bangladesh and Indonesia, among others

Cambodia: that the government has announced financial support for garment factory workers without work during the current lockdown restrictions.

The allowance will be paid in KHR and depends on the number of days for which the contract is suspended. That is: 60,750 riel (US$15) for the suspension of work for 7 to 10 days; 121,500 Riel (US$30) for 11 to 20 days work suspension; and 162,000 Riel (US$40) for suspension of work from 21 days to 1 month.

29 July

Bangladesh: Clean Clothes reports that Bangladeshi human rights defender and former child worker Kalpona Akter has written an open letter to European commissioners calling them to introduce strong rules that also give victims of corporate abuses access to justice in European courts.

She remembers the deadly Rana Plaza tragedy, still.

“Risking our lives like that was the only way to find out which companies sourced from the Rana Plaza factories, and those labels were the only hope to at least get some compensation. It took us weeks, but we identified about 30 brands. Many of them had nice sounding codes of conduct that had made no difference,” writes Kalpona Akter.

She calls for the new rules to include mandatory value chain transparency so that everyone can easily trace a company’s production sites, or a T-shirt’s origin.

Media report that Bangladesh’s lucrative leather industry has a major child labor problem, a new study by the Institute of Development Studies’ Child Labour: Action-Research Innovation in South and South-Eastern Asia (CLARISSA) program has found.

Based on interviews and observations of more than 150 children working 12-to-14-hour days, six days a week, the study uncovered rampant use of child labor in 96 percent of the “hidden” informal leather sector. The children observed few, if any, safety measures to protect them from toxic exposure or risk of injury at work.

The Covid-19 pandemic has only increased the risk of child exploitation. Lay-offs for adults meant that a number of children became their families’ chief breadwinners but weren’t always able to deliver. Lockdowns that shuttered most leather tanneries and factories for three months in 2020 left most child laborers without jobs and their families in dire straits.

Nearly half of the children interviewed said they weren’t able to buy food during the COVID-19 pandemic, eating only once per day as a result. Others reported having to resort to high-interest loans to pay their bills. Just 2 percent of respondents said they received support from a government food support program.

Cambodia: Media report that Cambodia’s Labour Ministry has signed an agreement with the US-based Solidarity Center, which will focus on protecting workers’ rights in sectors such as garment manufacturing.

The NGO, formerly known as the American Center for International Labour Solidarity, sought out closer ties with Cambodian authorities to strengthen the implementation of labour-related practices in the country.

Media report that eight provinces, most of which border Thailand, will be under a 14-day lockdown, starting from July 29 until Aug. 12. Cambodian migrant workers in Thailand, some of whom work in the garment industry, have been asked to delay their return to Cambodia until the lockdown ends.

28 July

Bangladesh: United Steelworkers, the largest private sector union in North America with more than 225,000 members in Canada, is contributing $45,000 in emergency relief to Bangladeshi garment workers reeling from the effects of the COVID-19 pandemic. The emergency funding is being provided to its long-time partner the Bangladesh Center for Workers Solidarity (BCWS) to assist workers in dire need of support.

Cambodia: Media reports workers union representatives in Cambodia are still hopeful that overflowing order books will be instrumental in garment workers getting a more favourable deal from the upcoming 2022 wage talks.

Many factory workers in permanent employment are now being expected to work overtime to ensure demand from the US and Europe is met.

However, Collective Union of Movement of Workers president Pav Sina is still unsure about how much the union should ask for and says he expects negotiations will be tough as he presses for a wage increase next year.

“We will have to wait for negotiations and review the economic and social situation before we know how much to raise our demands,” he told the Khmer Times. However, he says garment workforces need to be compensated with higher base pay as they continue to work overtime during the latest rise in COVID cases.

Media report that the government has provided financial assistance to 59,012 workers from 175 factories in the garment, footwear and bag industry located in lockdown areas in Phnom Penh, Kandal province’s Takhmao town and Sihanoukville.

A one-time payment of 160,000 riel ($40) is available through electronic payment service provider Wing. For workers to withdraw the money they must bring their Cambodian ID card and phone number to the nearest Wing agent.

Cambodian Apparel Workers’ Democratic Union president Ath Thorn welcomed the government’s assistance to workers in lockdown areas. He said it helped to some extent with their hardships.

However, Thorn added that if the government provided an allowance every month, it would be even better because the lockdown had lasted long.

Global: A report released in June looking at the unequal impacts of Covid-19 on global garment supply chains has now been translated into four languages; Spanish, Amharic, Tamil and Burmese.

Translated reports available here.

Vietnam: Media report that a trade group representing Gap, Adidas and other global fashion brands is asking the U.S. and Vietnamese governments to help vaccinate workers in the Southeast Asian country's vital garment industry against COVID-19.

In a pair of letters sent Tuesday, the American Apparel & Footwear Association asked U.S. President Joe Biden to ship more vaccines to Vietnam, and for Hanoi to prioritize jabs for the garment and shoe sector, which has seen a wave of factory shutdowns due to surging coronavirus cases.

With the lowest vaccination rate in Southeast Asia, Vietnam has put health care workers and the military at the top of its priority list for jabs. The apparel association, which said its members include 1,000 large fashion brands, asked Vietnam's Prime Minister Pham Minh Chinh to add textile and clothing makers to the list.

27 July

Sri Lanka: Media report that Sri Lanka’s leading garment manufacturer, Brandix has responded to an article by the Human Rights Watch which stated that following a Covid outbreak in October, trade unions filed a complaint with the Human Rights Commission of Sri Lanka alleging that soldiers “rounded up” 98 workers in the middle of the night and arbitrarily detained them in an unsanitary quarantine facility.”

Brandix says that the workers mentioned does not refer to Brandix employees. It also says that a mass scale PCR testing was conducted on the entire workforce at the Minuwangoda facility where a large number of team members were found COVID positive, and given support.

Bangladesh: The Daily Star’s latest editorial says now is the time to act on backlogged factory inspections. Citing the recent July 10 fire at the Hashem factory, it says; “Such a catastrophic violation of human rights portrays a negative image for Bangladesh and affects the credibility of our international commitment to protect fundamental human rights. It is high time that we revisit and remodel our legal and policy framework that exists for the workers' safety.”

Reportedly there had been an inspection in the Hashem Factory by the Department of Inspection for Factories and Establishments (DIFE) just a month before the fire.

They call for the re-examination of the DIFE; “the number of inspectors is highly inadequate compared to the vast numbers of factories and establishments in the country.. Having such a shortage of manpower means that the authority essentially has to prioritise among sectors and naturally that will leave out a large number of factories and establishments from inspection.”

Media report that despite severe lockdown restrictions, Dhaka’s streets are busy with private hire vehicles and transport carrying people across the city.

Australia: The Washington Post reports that an Australian clothing company Lorna Jane trumpeted “anti-virus activewear” with an advertising campaign for apparel covered in a “groundbreaking” spray called LJ Shield that the company claimed would eliminate and repel covid and other viruses, bacteria and fungus.

There was no scientific evidence Lorna Jane’s clothes did any of those things, government regulators said. On Friday, a federal judge ordered the company to pay $3.7 million for violating the country’s consumer protection laws, calling the clothing maker’s conduct “exploitative, predatory and potentially dangerous.”

Jordan: Media report that Jordan’s garment industry did not witness the pandemic’s worst impact, proving to be ‘relatively’ resilient in its adaptability to new trends, according to Better Work Jordan Annual Report 2021.

Despite the resilience, COVID-19 has exposed some weaknesses in the sector as well, the report said. “Some factories had severe violations, such as forced labour, inaccurate and late payment of wages and reductions in the number of meals provided to workers,” it said. The 12th BWJ annual report also showed that the country’s garment exports in 2020 were valued at $1.6 billion and made up 22 per cent of all exports.

Cambodia: The exports of garments, footwear and travel products and other finished textile goods from the Southeast Asian nation of Cambodia in the first half (H1) of 2021 increased by 0.9 per cent year-on-year, according to the data from the country's general department of customs and excise. These goods constituted 57 per cent of all goods exported by the nation.

26 July

Thailand: Media report that the Human Rights and Development Foundation (HRDF) has called for the Thai government to provide COVID-19 assistance packages to migrant workers without discrimination.

Employees who are affected by new strict restrictions imposed in the country will be compensated requiring 50% of wages, up to 7,500 Thai Baht, if they are social security insurers. But only workers holding Thai national ID cards will be eligible for the cash hand-out remedy, effectively cutting off support for many migrant workers, many of whom work in the garment factory industry.

Local media report that the Thailand-based project officer at the Center for Alliance of Labor and Human Rights (CENTRAL) has said that nearly 9,000 Cambodian workers in Thailand have been infected with COVID-19 in “red zones”, which include a curfew, limited business activity, the closure of all construction sites and a freeze on travel for migrant workers.

Cambodia: The New York Times reports that the Cambodian government has set up a system of forced quarantine centers that patients say are run more like makeshift prisons than hospitals. No one is allowed to leave until they test negative — and most people are stuck for at least 10 days. Lavish weddings halls, the preserve of Cambodia’s elite, have been used as Covid quarantine centres with high levels of security.

Thon Nika, a 41-year-old shift manager at a local garment factory, was fully vaccinated in May, but tested positive at work and spent two weeks, without any Covid symptoms, in the Koh Pich quarantine center.

“The vaccine isn’t protecting us, and there are a lot more cases than they say,” she said.

Khun Tharo, a veteran activist and program manager for the Center for Alliance of Labor and Human Rights, said more than 700 factories had closed down since last year, leaving more than 500,000 garment workers in the teeth of the pandemic.

“The government has prioritized the economy, not the safety of the workers,” he said. “Workers who are afraid to go to an exposed factory or to a treatment center are being pressured to go back to work. They have no choice, if they don’t go back to work they’ll have no income to survive.”

Bangladesh: Media report that the Gazipur district administration conducted a mobile court operation today and fined Tk 10,000 (US $117) to Unimas Sports Wear for running the factory, violating the government's directives for keeping garment factories closed till August in the latest national lockdown restrictions.

38 factories are running their operations across the country during the 14-day strict lockdown that began on July 23, most of them non-garment factories.

Indonesia: Media report that the government on Monday loosened a shutdown despite warnings it could unleash another Covid-19 wave.

President Joko Widodo said Sunday that a partial lockdown imposed in early July would continue until August 2 even as the highly infectious Delta variant tears across the vast archipelago nation, which has overtaken India and Brazil to become the global pandemic epicentre.

Indonesia’s textile industry is one of the largest in the world, employing over 2.5 million people and generating over $13 billion in exports annually.

23 July

Global: Media cite a new report published by researchers from the universities of Liverpool and Nottingham suggesting that amid the global pandemic, commercial and operational risks were prioritised by companies ahead of modern slavery concerns.

'Implications of COVID-19 for modern slavery challenges in supply chain management' assessed almost 500 managers in relevant positions, and held focus groups with expert practitioners to determine the scope of supply chain disruptions and the subsequent actions.

It found that whilst the managers of companies, including retailers, demonstrated a “small but significant” increase in their attention to modern slavery challenges exacerbated by COVID-19, it was often overlooked at times of operational uncertainty.

Read the full report here

Bangladesh: Media report that members of the Bangladesh Army, Board Guard Bangladesh and police set up check posts at different points on roads across the country as COVID restrictions resumed. Restrictions between July 23 and August 5 would be stricter than earlier ones, state minister for public administration Farhad Hossain told journalists on Thursday.

‘Like all offices, garment factories and export-oriented industries will be closed during these restrictions, this time the restrictions will be stricter,’ said state minister Farhad Hossain on Thursday.

Dhaka Tribune reports that people entering Dhaka in the morning had to walk for hours due to suspension of public transport.

Dhaka's streets were almost empty as no public vehicle was available, and all shops and malls, offices and factories remained closed till the end of the latest lockdown measures.

Vietnam: Media report that Vietnam garment makers face tough decisions between creating “bubbles” or choosing a temporary shutdown for manufacturers in Vietnam.

On Friday, as the two-week lockdown on the economic powerhouse and manufacturing base of Ho Chi Minh City came up for review, authorities announced an extension of lockdown measures lasting until August 1.

“All I can say is that the stress levels are really high, and for a factory that has more than 500 workers it is not quite worth it in terms of organizing the food and living conditions in these makeshift conditions. As Directive 16 will be implemented more strongly from this week, it will be harder to make it work,” a factory owner told Sourcing Journal.

There are more than 6,000 factories in the sector in Vietnam, which employ more than three million workers. More than half of Vietnam’s apparel factories are located in the Mekong and Dong Nai areas. In Hanoi, the requirements for factories, agencies and enterprises is to have Covid testing for workers every three to five days.

Cambodia: Media report the response to a Clean Clothes’ report finding that more than 780,000 workers in Cambodia's garment and footwear sector lost $109 million in wages during lockdown, the president of the Cambodian Labor Confederation (CLC) said that garment workers in Cambodia lost the wages due to salary cuts, suspension of work and dismissals.

He added that the unions will try to hold brands to account and that global brands’ owners should have obligations to help or provide financial benefits during lockdown, or when workers are in trouble because they have benefited from the labor force.

22 July

Global: Come and join “Solidarity in Claiming Back Wages and Benefits of Workers during the COVID-19 Pandemic” on 22 July 2021 (Thursday) at 8PM-10:PM Manila (2-3pm CET), organized by both the Migrant Forum in Asia and Clean Clothes. Register here to join: https://bit.ly/3wcrZzF

Cambodia: Media report that the Cambodian government has relaxed Covid-19 rules for garment factory workers. Four business associations independently submitted letters to the government appealing for reprieve from some of the strictest restrictions.

These were the Garment Manufacturers Association in Cambodia (GMAC), Cambodian Federation of Employers and Business Associations (CAMFEBA), Cambodia Footwear Association (CFA) and Japanese Business Association of Cambodia (JBAC).

Cambodia Footwear Association president Ly Kunthai said the government was attentive to the appeals of industry players in its decision-making, seeking to ease their burden during these trying times.

“We’ve now obtained solutions from the government that will help us, as factories grin and bear a wide range of issues during the Covid-19 pandemic,” he said.

Bangladesh: Bangladesh apparel factories close from 23 July as part of a two-week complete lockdown enforced by the Bangladeshi government to reduce the rising numbers of Covid-19. All apparel factories will have to close for two weeks after Eid-ul-Azha celebrations, according to media reports.

The latest lockdown will start from 6am (Bangladesh time) on 23 July and will end at midnight on 5 August.

Sri Lanka: Human Rights Watch has warned that the Sri Lankan government, factory owners, and international clothes brands sourcing from Sri Lanka should protect the safety and employment rights of garment workers during the Covid-19 pandemic.

President Gotabaya Rajapaksa ordered garment factories to remain open despite a strict lockdown imposed on May 21, 2021. Trade unions and public health inspectors have reported numerous virus outbreaks in factories, as well as in the congested boarding houses where many workers live, and alleged that employers were under-testing and under-reporting cases to maintain production levels.

21 July

Global: Large swathes of apparel-producing areas in Asia will be underwater by 2030. Media cite analysis released by the International Labour Organization, which overlaid maps of rising sea levels onto factory locations showed, threatening thousands of suppliers with submersion unless they relocate to higher ground.

While larger, trans-national suppliers may be able to shut down facilities in vulnerable areas and consolidate production on higher ground, smaller-scale suppliers will be most impacted, the paper's authors said, highlighting the example of Bangladesh - the second-largest apparel exporter.

Myanmar: A quarter of a million garment workers in Myanmar have lost their jobs following the military coup in February, reports Ecotextile, citing a new study by the International Labour Organization (ILO).

The ILO says the coup, on top of the economic impact of the coronavirus pandemic, has caused a deep employment crisis in Myanmar with the equivalent of 2.2 million jobs lost so far this year.

Malaysia: Media reports that The Federation of Malaysian Fashion, Textiles and Apparels (FMFTA) recently urged the government to allow the industry to resume operations as part of the country’s national recovery plan. Manufacturers and retailers have been facing losses amounting to RM163 million per day due to the shutdown.

Pakistan: Media reports that the value of textile and garment exports from Pakistan increased by 22.94 per cent year-on-year (in dollar terms) in the fiscal year 2020-21 ending June 30. During the period, Pakistan earned $15.400 billion from textile and apparel exports, compared to exports of $12.526 billion in July-June 2019-20.

Bangladesh: Media reports Chinese company Vanessa Enterprise Ltd has signed a $41.77 million deal with Bangladesh Export Processing Zones Authority (Bepza) to produce ladies garments in Ishwardi EPZ in Pabna. Some 4,028 Bangladeshi nationals will be employed in this factory.

20 July

Global: Several media outlets report on the report launched yesterday estimating workers’ income losses during the pandemic. This includes an interview by TRT world with one of the report’s authors.

Bangladesh: The Dhaka Tribune reports how order cancellations and brands and factory owners’ behaviour during the pandemic is causing workers to experience large drops in income, job losses and union-busting. This had extremely detrimental effects on workers as many of them had never been able to build up savings. One worker declared: “Those who have worked 2/3 months or 6 months/1 years here are being sacked. The management is saying that we don’t need you anymore, we have excess workers. But then, they are rehiring them at a lower salary. Those who were paid Tk9,000 are now paid Tk8,000.”

Media report that while income growth of wage earners in Bangladesh dropped to a six-year low in the last fiscal year, inflation on food prices continues to be on the rise.

Media report that factory owners associations have in a letter last week urged the government to allow export-oriented factories to operate during strict restrictions planned from 23 July 23 to 5 August, saying that otherwise orders would be lost. Other media reports say that the leather sector and PPE manufacturers will be exempted from the lockdown but that the government had not yet decided to the call to allow the apparel industry operate during this period. Pending a decision, articles say, workers had trouble deciding what to do and many went home before the Eid holidays, as they are unsure whether factories will reopen after.

The factory owners’ association BGMEA reports that 99% of their member factories have paid Eid bonuses. The Industrial police however reported that 477 factories had not paid the Eid bonuses by the end of the last working day before Eid.

Media report that the Palala garmanṭasa factory in Gazipur metropolis has been accused of locking the gate without paying the workers two months salary including Eid bonus.

India: Media report that garment export factories and other firms in different parts of India, including Tirupur, Surat and Chennai, operate on limited workforce in absence of migrant workers.

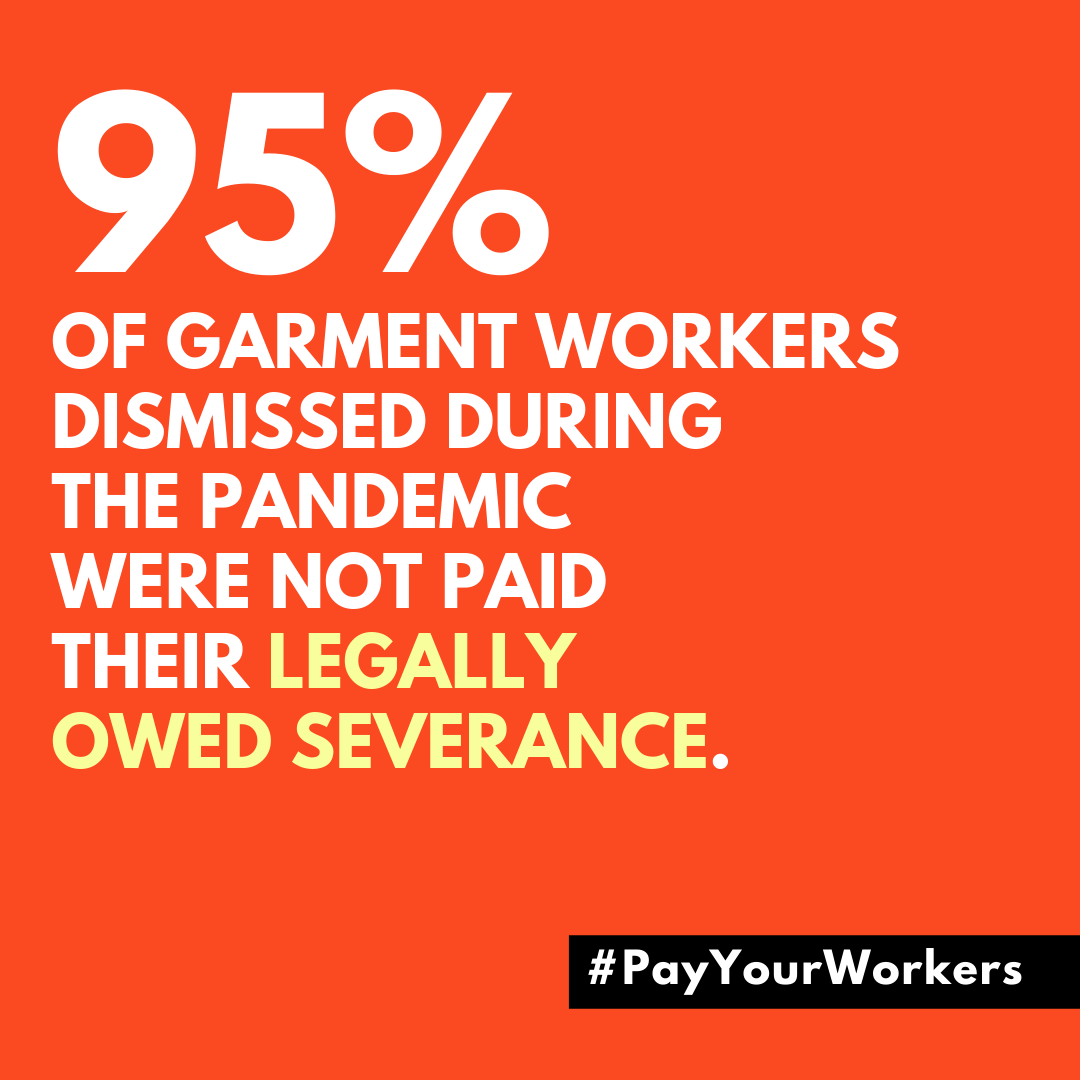

Indonesia: A new film launched by Clean Clothes Campaign today, called “How to steal your worker’s future” shows the importance of severance payments for workers upon dismissal and showcases through the lives of two Indonesian workers how worrying it is that many workers during the pandemic are not receiving their legally owed severance.

Media report that textile, garment and shoe factories are becoming a cluster for the spread of Covid-19. Unions say this is caused by the fact that many factories are still operating on 100% capacity in cramped conditions.

Sri Lanka: The Sri Lankan finance minister invited garment industry stakeholders to discuss the future of the sector in the light of the pandemic, however failing to invite union representatives.

Tunesia: Media report that garment and textile factories in Tunesia are hit hard during the pandemic, which causes labour rights violations and dismissals to spike. One worker who had not been paid for four months told Thomson Reuters: “How is there no money? We are working. The exports are going out as they always do.”

Vietnam: Media report that two Nike footwear suppliers in Vietnam — Chang Shin Vietnam Co. Ltd. and Pou Chen Corp. — have stopped manufacturing, in response to a regional lockdown. Other reports say also four Feng Tai factories, another Nike supplier, have closed. As a result Nike could run out of sneakers made in Vietnam.

19 July

Global: Clean Clothes Campaign today released a report estimating that garment workers have lost almost 12 billion in income between March 2020 and March 2021. More detailed estimates for seven Asian garment producing countries shows that workers have continued to steadily lose income during the pandemic. Workers in all researched countries, except for Indonesia, are dealing with a wage gap that is at least two times bigger than their average monthly wage. An estimated 1.6 million garment workers were dismissed in the seven countries during the pandemic and lockdown periods, with many dismissed workers not being paid their full legal entitlements to severance pay. The Financial Times reported on the price pressure by many brands on their suppliers as a major driver for this dynamic.

Bangladesh: Media reports that hundreds of readymade garment workers blocked the busy Dhaka-Gazipur Road on Saturday, demanding the immediate release of their salaries and other dues.Workers are said to be from Style Craft Garment, which has some 5,000 workers.

Media reports that, according to industry insiders, over 300 factories have not paid wages for June while workers of over 850 factories are yet to get Eid bonuses.

Babul Akhtar, chairman of Bangladesh Garment and Industrial Workers Federation (BGIWF), said some factories have not paid wages and bonuses to their workers yet, although the provision for payment is within the 10th day of the month.

“But every day, several factories are paying wages and bonuses. More than 80% of the factories have already paid wages. Hopefully, all the factories will complete the payment,” he added.

Media reports that Indian-owned company Sewtech Fashion Limited has signed an agreement with Bangladesh Export Processing Zones Authority to establish a readymade garments manufacturing factory in Chattogram. The investment is said to be $9.26 million.

Sewtech, sister company to India’s largest apparel manufacturer company Shahi Exports Pvt Ltd, said it will produce 3.36 million pieces of woven tops annually and create employment opportunities for 3,393 Bangladeshi nationals.

Cambodia: Media reports that the country exported (US) $8.201 billion in the first six months of 2021, a 17 percent increase compared to the same period last year. Exports of garment products; cloth, footwear and travel goods, amounted to $4.721 billion, a 0.9 percent increase over last year.

Vongsey Vissoth, permanent secretary of state at the Ministry of Economy and Finance, said recently that non-garment product exports will increase while garment exports are expected to see a contraction.

Vietnam: Media reports that Garment maker Dony decided to shut down because it could not provide food for hundreds of workers. The company planned to rent accommodation for its 400, but said it found ensuring three meals a day for them amid social distancing orders was difficult. Director Pham Quang Anh said cooking at the factory meant potential fires and explosions

16 July

Bangladesh: Media reports that garments, textile, terry towel and garment accessories makers sent a letter to the government, demanding apparel factories remain open during the countrywide lockdown. In the letter, they say that Bangladesh will lose $119.38 million per day from garment export alone if the factories remain shut for any reason, and that if factories are kept shut, the garment sector will lose many work orders and few billions of dollars.

They urged the prime minister to shorten the lockdown period so that the production continues in the factories to offset the losses.

Media reports that protests by garment workers and officers of Stylecraft Ltd have continued, as workers protested on the streets from 7:30am, demanding unpaid arrears of three years. The workers blocked a road, and continued protesting until 7:30pm. Workers are not only owed unpaid wages, but four years of annual leave and two years of Eid bonuses. The employers have continued to delay their payments.

Media reports that garment exports from Bangladesh increased by 12.55% in fiscal 2020-21 ending June 30, compared to exports of the previous year. However, the country missed its export target by 6.89%.

Cambodia: Media reports that the Ministry of Labour and Vocational Training has notified the release of cash subsidies for workers whose employment contracts have been suspended in garment and tourism, as part of the government response package for the fallouts of COVID-19.

3,180 workers/employees from 32 factories and companies are entitled for the 63th release of the cash subsidies.

The workers/employees suspended from jobs for 7 to 10 days will receive 60,750 Riel (about $15), from 11 to 20 days 121,500 Riel ($30), and from 21 to one month 162,000 Riel ($40). Also covered here.

Media reports that in response to research conducted by Clean Clothes Campaign and Cambodian unions on wage theft during the pandemic, Pav Sina, president of Collective Union of Movement of Workers (CUMW), said that factories had set aside no budget to pay workers during pandemic-related factory closures. Brands had not given them any extra funds to do so.

“...If they do not [supply funds], it means that they do not think about the workers’ impact but they think only about their income.”

Khun Tharo, a program coordinator at CENTRAL said brands should do more to ensure factories are following labour guidelines and should set aside funds to pay those who aren’t allowed to work during lockdowns.

“They have to consider subsidising wages to workers who are facing job suspensions during lockdown. They must work to support their suppliers to establish social support assistance to workers that make their products during this period.”

India: Media reports that 10% of Tirupur’s garment orders have been diverted to Bangladesh, Vietnam, Cambodia and China. The sector faced a 9% drop in exports during the first wave, but it is predicted that the impact will be greater this time.

Indonesia: Media reports that according to the Indonesian Trade Union Confederation (KSPI), the government’s emergency measures to ease the rapid spread of COVID-19 are ineffective, as all manufacturing factories are still working at 100% capacity. According to data collected in various regions of Indonesia, he reported that at least 10% of workers in the manufacturing or processing sector are affected by the virus.

Media reports that according to a survey conducted by the Indonesia Business Coalition for Women Empowerment (IBCWE), COVID-19 has led to workers, especially low-income workers, facing paycuts. Those in labour-intensive industries such as textiles, garments and footwear, have had wage cuts ranging from 25% to 50%.

Thailand: Media reports that in Chon Buri, three new COVID-19 clusters have been found, including a cluster of 30 cases at a garment factory in Pak Kret district. Chachoengsao also has a new cluster at a garment factory, with 10 cases.

Vietnam and Myanmar: Media reports that Hakers (supplies Tchibo and Hanes Brand) has closed its factory in Vietnam for two weeks due to the new wave of COVID-19. A factory in Myanmar has also been shutdown.

Vietnam: Media reports that businesses in Ho Chi Minh City have complained that it is impossible to implement the city’s new stay-at-work orders within the 24-hour deadline.

According to these regulations, enterprises can provide accommodation and food for employees on their premises, so they can operate normally. Otherwise, they must close down. A garment maker decided to shut down because it could not provide food for hundreds of workers, while cooking at the factory meant potential fires and explosions.

In relation to this, another article reports that while many businesses are taking measures to ensure accommodation for their workers, according to the chairman of HCMC Association of Garments, Textiles, Embroidery and Knitting, most factories in this sector have had to halt operations, as the number of workers is too large for them to ensure safe conditions, and it would also be very costly.

Media reports that two Nike suppliers have suspended production due to a COVID-19 outbreak. Changshin Vietnam, which employs 42,000 workers, will remain shut at least until Tuesday, with 177 infection cases. Pou Chen has suspended operations at its Pouyen Vietnam factory for 10 days, after 49 infections were detected at the plant.

Early on in the pandemic, Pouyen was forced to suspend operations for two days, after it was discovered violating social-distancing policies. It was quickly remediated and re-opened.

15 July

Bangladesh: Media reports that the discussion between apparel manufacturers and the cabinet secretary could not decide whether the garment factories will remain closed or open during the 14-day countrywide lockdown starting from July 23. Another meeting will be held to make a decision. More coverage here.

Cambodia: Media reports that Cambodia exported $357.8 million worth of garments, textiles, shoes and travel goods in the first six months of 2021, inching up 1.4%. Figures show the garment exports were produced in the special economic zones (SEZs).

Garment exports accounted for most of the total exports at $232 million, a 3.3% decrease compared with the same period last year. The EU and Japan markets were the biggest markets for the Kingdom’s garment products with a total amount of $77 million and $74 million, respectively.

Media reports that many Cambodian workers in Thailand are still waiting to receive their Covid-19 vaccinations, as workers must have legal working documents to receive the COVID-19 vaccine.

Center for Alliance of Labor and Human Rights (Central) official Loung Sophon said, “The Thai government should give the COVID-19 vaccine to all workers whether or not they have legal working documents because it is important to prevent the spread of COVID-19 in the country.”

China: Media reports that China's exports grew at a much faster than expected pace in June, as global demand led by easing lockdown measures and vaccination drives worldwide eclipsed virus outbreaks and port delays. Exports in dollar terms rose 32.2% in June from a year earlier, compared with 27.9% growth in May.

Thailand: Media reports that factory activity is projected to contract in the third quarter of the year, following the enactment of new COVID-19 emergency public activity restrictions (PPKM Darurat) that are expected to impact overall business activity.

Sri Lanka: Media reports that there are about 270 Community Vaccination Centres manned by tri-forces and health authorities currently operational countrywide, with garment workers included among those prioritised to receive the vaccine.

Media reports that In May, earnings on merchandise exports recovered by 52% year-on-year and 9% month-on-month (MoM). In particular, textiles and garments, driven by a high number of export orders to the European Union (EU), rose by a notable 69.2% year-on-year to US$ 372.4 million.

Media reports that MAS Intimates, the largest division of Sri Lanka’s leading apparel manufacturer MAS Holdings (Pvt) Ltd, established an Intermediate Care Centre for the treatment of employees, their families and the general public in the North-Western Province, and has been set up with special facilities to accommodate the needs of critical COVID-19 patients.

Vietnam: Media reports that 49 infections have been detected at the Pouyen factory (Pentland Brands, Nike, Asics, Mizuno, VF Corporation, Lacoste, New Balance, adidas supplier), which has been temporarily suspended.

Media reports that Changshin Vietnam Co., Ltd has suspended production for six days for all 41,000 workers at three factories, to prevent the spread of COVID-19.

Media reports that Eclat Textile Co., a Taiwan-based garment and fabric supplier, has suspended production at its plant for four days in Vietnam after cases of COVID-19 infections were confirmed among its employees. During this time it will launch tests for the employees and disinfect the plant. The company did not release any details about the infections, including how many workers have been infected and their health conditions.

14 July

Global: Media reports that there has been rollback on labour rights in the global garment industry due to COVID-19, as fashion brands pile pressure on their suppliers and, in turn, on factory workers, according to reports by labour advocacy groups including Asia Floor Wage Alliance and Worker Rights Consortium. In-depth studies from these organisations have found workers around the world owed wages and severance pay since the pandemic began.

Abdul Wasid, a garment worker who was sacked from his job at a Pakistani garment factory in the early days of the pandemic was rehired three months later – for lower pay and longer hours.. “I was desperate because I hadn’t earned anything for months after being fired and agreed to everything they said. Now I’m depending on small loans to survive.”

Bangladesh: Media reports that garment workers from Style Craft garment Ltd factory demonstrated and blocked a road demanding their dues and Eid bonus, for a second consecutive day.

The workers and staff have been demanding their dues for the last few months and observed protests in front of the factory several times The authorities yesterday were given an ultimatum to pay the dues by evening but failed to do so.

Chameli, a worker of the factory, said: "We don't need any new dates or promises. We need our salaries.”

The factory is yet to pay the workers for three months of the current year and four months of the previous two years. Also reported here.

Media reports that around 530 factories, mostly textile and apparel manufacturing units, could face labour unrest over non-payment of wages and festival allowances before Eid-ul-Azha on 21 July.

Media reports that manufacturers fear the apparel industry will suffer due to the government's decision to keep factories closed for 14 days amid a peak season for export and purchase orders, and say they are receiving a large number of orders for spring and summer clothing from the US and Europe. If the factories are closed for two weeks, they will not be able to supply the products in accordance with the lead time as per the purchase order, then foreign buyers will cancel the purchase orders or take advantage of the discounts, said apparel manufacturers.

Cambodia: Research by Cambodian trade unions and Clean Clothes Campaign has found that Cambodian garment workers producing goods for international fashion and sportswear brands, such as Adidas, VF, Target, Nike and Gap, were deprived of an estimated US$ 109 million in wages during the April and May 2021 national lockdown.

Unions and activists call on international brands to pay workers’ full wages throughout the duration of the pandemic and sign an enforceable agreement to prevent future pay theft. Also reported here.

Indonesia: Media reports that in surprise inspections by the Serang Regency Covid-19 Task Force in Serang, five workers at PT Shinta Woo Sung (a Nike supplier) tested positive for COVID-19.

Vietnam: Media reports that after COVID-19 infections were detected at the Tan Thuan Export Processing Zone in District 7, 29 enterprises have had to cease operations. Many said they have had to apologise to customers for potential late deliveries. For example, Pouyuen Vietnam (Pentland Brands, Nike, Asics, Mizuno, VF Corporation, Lacoste, New Balance, adidas supplier), the biggest employer in Ho Chi Minh City with over 56,000 staff, had to suspend operation due to worker shortages caused by COVID-19. If the company cannot negotiate with clients successfully, it will have to compensate for late delivery.

In another article on Pouyen Vietnam, media reports that the company will be closed for 10 days after the company said it could not fulfill the district's requirements on having all employees stay back at the factory and get the new COVID-19 tests every three days, instead of workers moving back and forth between their residencies and the factory.

Cu Phat Nghiep, chairman of the company's labor union, said the factory could not arrange for all workers to stay in the factory because there are too many of them while a majority of the factory has been occupied by machinery."

Media reports that as of 10 July, over 10,000 employees of the Vietnam National Textile and Garment Group (Vinatex) were unable to come to the factory, accounting for 10% of the Group's workforce. The company says they are facing the greatest difficulties resulting from COVID-19 since 01 May 2020.

Employees are unable to attend work due to positive COVID-19 cases and resulting blockades and restrictions on workers and factories.

Thailand: Media reports that migrant workers' rights activists slammed a decision by the Ministry of Labour to end a project to carry out active COVID-19 testing on 30,000 high-risk migrant workers from Myanmar, Laos and Cambodia in Metropolitan Bangkok. The decision, which appeared in a letter, cited scarce resources and medical personnel due to the latest coronavirus outbreak.

Koreeyor said that those at highest risk should have access to tests and medical care first. “It’s a failure and naivety on part of the state and will put everyone at risk. We should not be indifferent simply because they’re not Thai.”

Media reports that the cabinet has approved a 42-billion-baht package of financial assistance for workers and businesses affected by the lockdown, currently implemented in ten provinces to contain the COVID-19 outbreak.

Workers registered under Section 33 of the Social Security Act, will receive at most 10,000 per person for one month. Other workers registered under Sections 39 and 40 will receive a cash handout of 5,000 baht for one month as well. Employers and workers who have yet to be registered under the social security system will have to first register to become eligible to receive these benefits.

Media reports that many migrant workers have chosen to return to their home country, after the Prime Minister ordered the closure of worker camp sites across Bangkok, as a measure to curb COVID-19 transmission. Approximately 100-150 migrant workers are leaving daily.

Media reports that the Cabinet has approved a proposal to allow four groups of migrant workers from Cambodia, Laos and Myanmar to legally stay and work in the country until July 27 next year, in order to allow them to sort out their employment status and work permits.

Migrant workers from these countries who have lost their jobs due to the pandemic will now have 60 days to find a new job and register with labour authorities.

13 July

Bangladesh: Media reports that all factories have been ordered to close operations after the end of Eid from July 23 for 14 days.

The closure will continue until 5 August to contain the rising rate of COVID-19. Union leaders believe that it will have little impact on production, as it will take a while for production to start in full swing after the Eid holidays.

Media reports that the government has instructed garment factory owners to pay all dues, monthly wages and festival bonus by 19 July. The minister also instructed factories to decide on Eid holidays through discussion with their factory workers, in line with government Eid holidays.

Media reports that officers and staff of Style Craft garments factory demonstrated Tuesday demanding three months’ salaries and other dues pending for the last three years.

The workers and staff have been demanding their dues for the last few months and observed protests in front of the factory several times. Dissatisfaction spread among the staff in the morning when the factory authorities refused to pay their dues. Even though the workers joined work, the officers and staff formed a human chain on Dhaka-Joydevpur Road for an hour and later blocked the road.

Later they took position in front of the factory till evening.

Cambodia: Media reports that migrant workers returning from Thailand who are quarantining in centres along the border in Oddar Meanchey province are facing a shortage of facilities, including medicine, toilets and mosquito nets. The lack of mosquito nets is causing particular concern, as workers fear getting malaria or dengue more than COVID-19. A factory worker said that in addition to the shortages, officials appeared scared to get near them. “They detest us strongly,” he said.

Media reports that COVID-19 patients are being taken to crowded quarantine centres, with new arrivals having to sleep in tents or stay in a campus building with fewer bathrooms. Patients say they struggled with the stress, boredom and lack of information and doctor attention during their stay. Choub Chanda, a garment worker from Hi-Tech Apparel was admitted to a centre with some of her co-workers, and said, “At first, I felt so broken and scared at the same time...I’m quite stressed here because I could not go anywhere. Just staying in one place.”

Media reports that the Project Advisory Committee (PAC), a UN-backed advisory committee charged with ensuring labour rights and adequate working conditions in Cambodia's garment factories, has said that it will continue to engage with partners to improve the welfare of workers in the Cambodian garment, footwear, travel goods and bag industries. It further stated it is committed to preventative COVID-19 measures, and to supporting an environment where employers and worker representatives can engage in dialogue. The Committee called for joint action from all industry partners in Cambodia and internationally to support the garment sector to sustain the industry and the lives of the workers throughout the global pandemic.

Media reports that the government has said that COVID-19 has made women and girls more vulnerable. For example, women and girls, who generally have lower income and less stable employment face greater economic uncertainty from COVID-19, and are at the highest risk in daily life. As a result, the government says they are prone to falling into poverty, and face rising unpaid workloads that are pushing more women out of the paid workforce. A factory worker expressed her happiness regarding the government intervening to provide more social assistance to alleviate the hardships of the people, but said that if the government did not speed up the focus on helping women and girls, it would make them more vulnerable in life. In her case, the factory she is currently employed at is facing temporary closure due to infected workers.

Japan: Media reports that the Japanese government is asking the domestic apparel industry to check for human-rights violations among suppliers, noting that many companies in Japan are using migrant worker interns in production stages, from spinning to sewing..

The report says the apparel companies are responsible for grasping the entire situation along their supply chains.

Tunisia: Media reports that Tunisian garment factories, which mainly supply European fashion brands, have been hard-hit by the COVID-19 pandemic, with thousands of job losses and a rise in complaints about labour rights violations, including non-payment of severance pay and regular wages in the sector, as exports to the European Union plunged.

A garment worker who works at the Fada factory supplying shirts for Italian brands including Renato Balestra group, Lancetti and Il Granchio has not received her wages since March, and is racking up debts. Three other workers said they had been evicted from their homes, unable to pay the rent, because of the wage freeze.

Some workers are organising between themselves to fight for their rights, with Fada workers organising to negotiate with their employer, who has told workers they will be paid in August. If this does not work, the workers will go to court.

Turkey: Media reports that workers at Denim Kumaşçılık (aka Dynamo) in Lüleburgaz protested at the factory gates against the dismissal of four workers who were members of DİSK/Tekstil union. They demanded the reinstatement of the workers and recognition of union rights.

12 July

Bangladesh: Media reports that the International Labour Organization (ILO) has launched a ‘Behaviour Change Awareness Campaign’ to identify and reduce COVID-19 risks faced by garment workers in their workplaces and communities. The campaign aims to inform workers, their families and communities about COVID-19 symptoms to help them take precautions and prevention measures against the virus. Special emphasis has been put on COVID-19 health tips for pregnant and breastfeeding mothers.

Ethiopia: Media reports that due to the pandemic, the workforce at Hawassa Industrial park reduced from 35,000 workers, to 26,000. However, capacity has now reached 30,000. Due to the scarcity of new orders at the onset of the pandemic, the factories shifted to PPE production, enabling them to maintain the 26,000 workers.

Meanwhile, wages are still low, as workers depend on incentives to increase income, which are highly dependent on a workers’ ability to meet productivity goals set for them by supervisors.

India: In an op-ed, the All India Trade Union Congress in Bengaluru called on the government to treat factory workers as frontline workers and ensure they are vaccinated and receive benefits on a priority basis. Workers have continued to work during the second wave, in factories that do not allow for social distancing protocols to be followed, and with limited support from the government to ensure health and safety measures are in place.

Sri Lanka: Media reports that Human Rights Watch has called on the Sri Lankan government, factory owners, and the international clothes brands sourcing from Sri Lanka to protect the safety and employment rights of garment workers during the pandemic, as factories remain open and numerous outbreaks are reported in factories and the congested boarding houses workers live in. Reports have shown inadequate occupational health and safety measures put in place in factories, while workers who are taken to quarantine facilities have their absences deducted from their annual allowance of 14 days unpaid leave. The police and military personnel are also intimidating workers to stop them from speaking out.

An activist who had assisted workers who were sick with the virus said, “The employers are busy with their orders and workers are not given PCR [Covid-19] tests, because if they are positive, they will not be able to employ them in production.”

Thailand: Media reports that Cambodian workers in Thailand are reporting losing their jobs and starving after the Thai government suspended factories, to prevent the spread of COVID-19. According to a worker from Cambodia, Cambodian workers are facing unpaid wages and food shortages living in the dormitories. In one case, a factory recently laid off about 70 Cambodian workers for no apparent reason.

11 July

Bangladesh: Media reports that one-third of young women who were employed before the pandemic were out of jobs as of January 2021, due to the impact of COVID-19. The rate of unemployment following the pandemic is three times higher in women at 29%, than that among men at 11%.

Among those who found a job later, income recovery dropped by 21% for female youths and by 10% for male youths as of January 2021.

Media reports that while garment workers continue to work during the lockdown and are having to walk or travel in private vehicles with other workers due to no public transport, they do not speak out, in fear of losing their jobs. While 70% of workers live close to their factories, 30%, live in housing further away, and very few factories have transport for those workers.

Rahima Akhter, Shefali Begum and Khorshed Alam, some of the garment workers, said, "I have asked the factory owner to make arrangements for transportation since the corona infection started. They did not pay attention to this issue. Didn't even feel the need. That's why we don't want lockdown. Our factory is open even if everything is closed in lockdown. If you say something, the owner says to quit the job. If you don't come to work one day, your salary will be deducted. I was forced to come to the factory in a rickshaw-van with double the fare. No one sees our suffering, no one evaluates it."

Turkey: Media reports that SML Label factory workers of the Dev Tekstil union have continued to protest in front of the factory for over 4 months against their dismissal, which was done under the context that the business was sinking. “You are responsible for our dismissal,” the workers said to Decathlon, H&M, Mango and ZARA.

Addressing the Decathlon, H&M, Mango, Tommy Hilfiger and Zara, one of the protesters said, “You are a top employer. In addition, in accordance with the Global Framework Agreements you have signed, national and international laws, conventions, regulations, etc., especially the right to organize. You are responsible for its implementation. You have responsibility for the attacks faced by the workers whose rights are violated, especially the right to unionize with your suppliers. If you do not remember that you are responsible, we will continue to come here...We want our job. We, as SML Label resisters, will not give up our struggle. We will protect our rights, our future."

Vietnam: Media reports that according to the Director of Viet Thang Jean Company (Gap and Fast Retailing – parent company of Uniqlo – supplier), three of its factories are located in the blockade area, as COVID-19 continues to spread. In response, the company has organised for over 1000 workers to stay at the factories to continue production. The company had to spend more than 1 billion VND on tests and to buy equipment for workers staying at the factories. "We have orders, customers are fixed, if we stop now, we will lose credibility, and it is easy to lose customers to other countries."

Media reports that six more foreign companies in Ho Chi Minh City with over 36,000 workers have had to shut down operations due to COVID-19 infections or isolated individuals in closed areas.

According to Long Rich (Brooks Sports supplier), a Taiwanese shoe manufacturer, about 4,000 workers had to take 14 days off work after a COVID-19 case was detected at the factory, disrupting production. Another Taiwanese shoe manufacturer Freetrend Industrial Vietnam, with about 21,000 employees, also suspended operations to re-evaluate COVID-19 measures, after it detected cases of COVID-19.

10 July

Bangladesh: Media reports that the Garment Workers Front has demanded workers of Sinha Group (supplies Levis) and Style Craft (supplies River Island, New Look, Next, H&M, and Debenhams) receive their unpaid arrears, after having protested for over three months.

Leaders say the factories are open and production is underway amid lockdown, and that many factories are yet to pay the workers' wages under the pretext of lockdown, even though there is a provision to pay the previous month's wages within 7 working days of every month. Furthermore, even though there are only 10 days left for the Eid holiday, almost no factory has paid Eid bonus to the workers.

The leaders said that by July 15, workers will have to be paid all dues including Eid bonus, June's salary and overtime wages, equivalent to at least one month's wages.

Indonesia: Media reports that due to lack of orders, minimal sales and the subsequent accumulation of stock, 50% of factories in Sukamaju Village in Majalaya Distrct, Bandung Regency have temporarily closed, which has led to temporary layoffs.

9 July

Asia: Media reports that Asia Floor Wage Alliance has filed legal complaints against fashion brands in major garment-producing countries across Asia, in an attempt to hold the global fashion industry legally accountable for wage violations during the pandemic.

Ashim Roy, an Indian trade unionist and AFWA member, said “Our core argument is that the reality of fashion supply chains is that brands do not just buy garments. They determine and control every step in the production process of that garment being made and so they should not be able to continue to argue that the workers who make their clothes do not work for them.”

Bangladesh: Media reports that due to the ban on public transport during lockdown, many garment workers are having to walk long distances to reach their factories, as the affordable housing they are living in is further away from the factory. Some workers are reported to have had their wages deducted for being one or two minutes late to the factory.

Media reports that according to a new study, garment workers are still in a vulnerable position as they can hardly follow health protocols to protect themselves from COVID-19, as they live in congested spaces where ensuring social distancing is difficult.

Media reports that labour rights groups have urged the government to bring garment workers under the vaccination programme on a priority basis, as they continue to work amid the surge of COVID-19 infection and death. Labour leaders health and safety guidelines were not implemented in many factories and many workers were walking a long way to join work due to lack of transport. Demands included 70% of of monthly wages of workers as risk allowance and Tk 200 as transport allowance for each worker in case of failure of factories in providing transport during the lockdown, suppliers to not terminate any workers during the pandemic, transport facilities with proper health and safety, and field hospitals

The labour rights group said that export earnings increased by 15% in last fiscal year but factory owners were not willing to invest in the safety of workers amid the pandemic.

Media reports that the management of garments maker Kwun Tong Apparels is trying to sell off the unit inside Adamjee Export Processing Zone, which suppliers Lidl, Tu Clothing, Amazon and George At Asda, due to suspended production, cancelled orders, and deferred payments from brands during the pandemic.

They said that the company faced big discounts and order cancellations from brands and retailers, with one US-based retailer cancelling orders worth $20 million and another, who had to be provided a discount of $25 million.

"The buyers have demanded long deferments in making payments that no one can survive as the banks will not spare the loan repayment. Nobody can survive as the retailers do not pay and the profit margin is so low."

Cambodia: Media reports that the government will launch the second phase of cash assistance for those who have been seriously affected by the COVID-19 lockdown period on July 13. Lockdown affected factory workers will receive 160,000 Riel ($40) each as a one-off subsidy.

Media reports that Svay Rieng Provincial Administration announced the identities of 60 new Covid-19 cases, 41 of whom are garment factory workers.

Indonesia: Media reports that Karawang Regent Cellica Nurrachadiana was irritated by a textile factory in Karawang Regency after discovering it had failed to report dozens of its employees who had been exposed to COVID-19. She was also upset that the factory did not form a task force to deal with the COVID-19 outbreak.

Media reports that hundreds of workers from CV Garuda Solo Perkasa or GSP demanded severance after the textile company was confirmed closed.

Myanmar: Media reports that while the military has steered clear of a country-wide lockdown, it has imposed stay-at-home orders at townships in several states in an effort to curb the spread of COVID-19 which could put more factories at the risk of closure and likely form new clusters of COVID-19 cases.

In the factories, there are no masks they are very crowded and there is no social distancing.

South Africa: IndustriALL reports that industrial primary health care clinics in the garment sector, run by the Southern African Clothing and Textile Workers Union (SACTWU) and some employers, are now certified by the department of health to carry out vaccinations. The clinics, which have the capacity to vaccinate at least 6,000 workers per week, will be linked to the national vaccination roll-out programme.

Thailand: Media reports that three more garment factories have been shut down as COVID-19 infections continue to rise, with more than 1,500 cases confirmed in one week in Tak province. Two of the factories are owned by Top Form (a Hong Kong-based OEM of bras), in which a union official said about 100 cases have been discovered. Currently, access to eight garment factories and at least five dormitories, mostly occupied by Burmese workers, is restricted in Mae Sot Township.

Turkey: Media reports that Farmers Shoe factory workers, members of the Leather Weaving and Textile Workers' Union (DERİTEKS), made a press statement in front of the factory against unpaid leave, pressure and threats. Reading the statement, DERİTEKS Organizing Secretary stated that dozens of workers who were supposed to be back at work were put on unpaid leave as the laws were restored during the pandemic period at the Farmers Shoe factory. He said the factory management unilaterally imposed unpaid leave on workers for different periods from 4 days to 1 month without their approval. He said that although the unpaid leave arrangement ended on July 1, bosses wanted to continue arbitrary practice, and urged farmers' shoe management to respect workers' right to union and to end arbitrary unpaid leave.

Vietnam: Media reports that while factories are receiving abundant orders from brands, they are suffering from labour shortages, as many workers have had to isolate. According to reports, Hoang Thi Loan Textile and Garment have 1/3 of their workers currenting working, Minh Anh Kim Lien Garment (Target supplier) lacks 500 employees, and Prex Vinh (Kido Vinh)'s capacity is still less than 90%.

Many workers have had to isolate, causing production line disruptions, due to blockades in some localities and strict control of transport vehicles.

Further reports on the labour shortage highlight that the Bac Giang Garment Corporation (LGG) in northern Vietnam is experiencing a major labour shortage with only 10% of its employees working, as most workers are isolating, with the province being the second largest COVID-19 hotspot in the country. As a result the company is struggling to fulfil orders.

Footwear and bag producer Pousung Vietnam has had nearly 3,000 employees, or 12% of their total workforce, isolate.

Vietnam: Media reports that nearly 7,000 workers employed at 46 factories will now be able to stay at their factory for at least two weeks to avoid disruptions to production in the event of a COVID-19 outbreak. Workers who agree to stay will receive 1-2 million VND per person. As of last night, Binh Duong, which has 29 industrial parks and 12 industrial clusters , recorded 918 infections, more than half of which were workers.

Media reports that authorities have lifted the blockade put in place following a positive COVID-19 case at Asia Garment.

8 July

Bangladesh: Media reports that garment manufacturers have called upon the government to step in and address the scarcity of containers which has, along with congestion at transhipment ports, has resulted in significant delays in shipments to buyers.

Media reports that thousands of garment workers in Narayanganj and Gazipur blocked three major highways for hours demanding the payment of outstanding salaries and allowances.

Thousands of workers of Opex and Sinha Group (supplies Levis) blocked the Dhaka-Chittagong and Dhaka-Sylhet, while, workers of Style Craft Ltd blocked the Dhaka-Gazipur Highway for two hours.

Opex and Sinha Group workers said that they did not receive their salaries for the last three to four months and the authorities concerned have shut down factories without any prior notice. They did not receive their Eid bonus during Eid-ul-Fitr either. Meanwhile, Style Craft Ltd (supplies River Island, New Look, Next, H&M, and Debenhams) employees claimed that they are owed wages for three months of last year and overtime allowances from over the past three years.

According to further reports, one worker from Style Craft’s garment factory said factory management had promised to pay the wages several times, but had later reneged on their commitment .Staff demanded their pay on Thursday morning but factory management deferred again, promising to pay by July 15, which led to unrest among staff, and around 600-700 employees protesting. According to management they were not able to give backpay by July 7 due to the pandemic.

Canada: Media reports that Canadian apparel imports remained stagnant with just 3.30% monthly growth in May this year compared to April However, year-on-year, its shipment value increased by 110%. Though all major apparel manufacturing countries increased their shipments to Canada year-on-year, many of them declined on a monthly basis. Excluding China, Pakistan and Italy, all other countries in the top 10 declined in their apparel exports to Canada compared to April.

Cambodia: Media reports that 92 garment workers from Meng Ieng factory (Target supplier) tested positive for COVID-19.

Media reports that Svay Rieng Provincial Administration announced the launching of the COVID-19 vaccination campaign for workers. Further reports highlight that the provincial administration announced it will start with people and garment workers who volunteer for a vaccination.

India: Media reports that among low-income families in industrial areas, predominantly informal sector workers, the economic shock of the second wave has been lower compared to the first wave, however its psychological toll has been higher than at the onset of the pandemic. The adverse effect on emotional well-being has not only persisted and remained high over the past year but appears to be worsening.

Media reports that three guest workers tested positive for COVID-19 immediately after their arrival to Tirupur. Guest workers from West Bengal, Bihar, Jharkhand and other states had started to return after the lockdown was lifted and garment units resumed full operations. As guest workers stay in small congested rooms, and work in small units with workers in close range to one another, the possibility of transmission is high.

Sri Lanka: Media reports that a COVID-19 patient suspected to have been infected with the Delta variant has been identified as a worker from an garment factory in Borella.

Thailand: Media reports that from October 2020 to June 2021, factory expansion projects decreased by 70.23% year-on-year, while the number of factory registrations went down by 6.33% year-on-year, due to the pandemic.

Media reports that the government is being urged by the Thai National Shippers' Council (TNSC) to speed up the allocation of COVID-19 vaccines to the manufacturing sector to increase exports. The group repeated its call for the administration to expedite vaccine distribution to cover all groups, especially workers in the manufacturing sector, to stop the spread of infection across the supply chain, which has led to factories halting production and postponing the delivery of goods to destination countries.

7 July

Asia: Asia Floor Wage has published a new regional study on the extensive wage theft over 2000 garment workers across Bangladesh, Cambodia, India, Indonesia, Pakistan and Sri Lanka have faced due to the practices of apparel brands during the pandemic.

Further reports highlight that according to the report, garment workers in Pakistan faced some of the highest rate of wage theft in the Asian garment industry, due to the provincial COVID-19 lockdowns that coincided with the cancellation of orders by many global brands.

Although the intensity of the crisis was felt most in April and May 2020, women workers, who are mostly employed in casual jobs, continued to bear the brunt of it even in early 2021 as most factories did not rehire women workers laid off in 2020, the report observed.

Cambodia: Media reports that Cambodia’s total exports were valued at $5.982 billion in the first five months of 2021, increasing by 1.6% compared with the same period last year. However, the export of garments decreased during this period.

Media reports that from January to May, Cambodia exported $139 million worth of goods to South Korea, a decrease of 0.4% compared to last year. Cambodia’s primary exports to South Korea included garments and footwear,

Reports via Twitter state that over two days, 137 workers at Meang Eang garment factory in Phnom Penh have tested positive for COVID-19.

Honduras: Media reports that in August 2020, 430 garment workers at Delta Apparel’s Villanueva plant were dismissed during the pandemic. Many of them had work-related musculoskeletal conditions and some were pregnant.